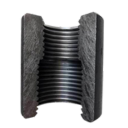

Cold Forged Coupler

Parallel Threaded Couplers

Parallel threaded couplers provide secure, efficient connections for rebar in construction, ensuring structural integrity.

Transition Couplers

ABOUT US

Precision-Engineered, Durable Rebar Couplers

- PARALLEL THREADED COUPLERS 70%

- COLD FORGED COUPLER 90%

- TRANSITION COUPLERS 80%

PROJECTS

COUPLERHUB

Why Choose Couplerhub

Cost Saving

Improvement in Concrete Flow

Easy to Install

Solves Rebar Congestion

Time Reduction

COUPLERHUB

Quality Assurance

REBAR COUPLERS

Excellence in every rebar coupler solution, tailored to your needs.

COUPLERHUB

Conventional Splicing VS Mechanical Splicing

Primitive Method

Couplerhub Couplers

SERVICES

On-site Threading

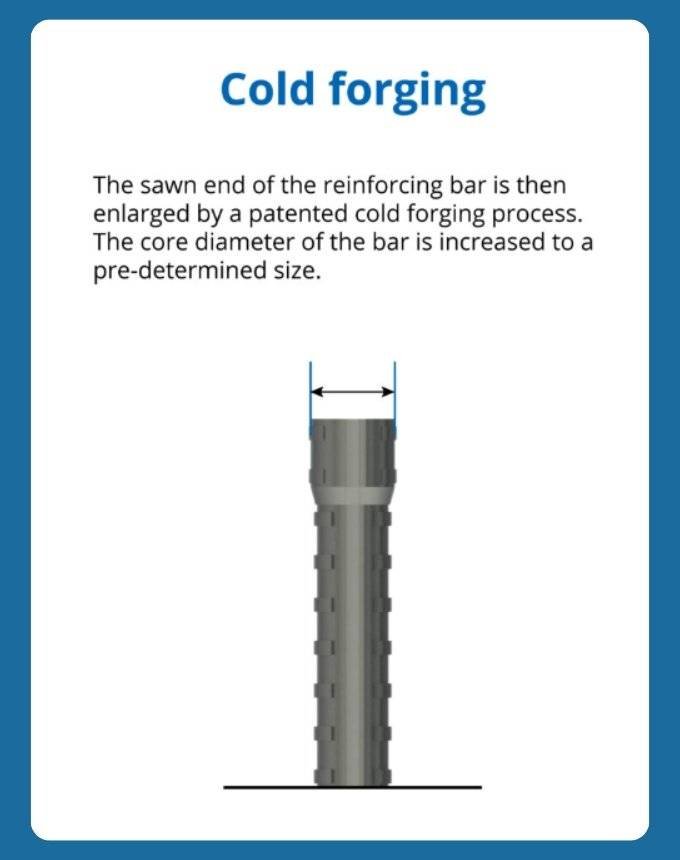

Rebar Cold Forging Machine

A rebar cold forging machine is used to create cold-forged couplers, which are essential components in reinforced concrete structures. This machine shapes metal without heating it, ensuring the couplers maintain their strength and durability while providing a secure connection between rebars. It’s a crucial tool in modern construction, offering efficiency and reliability in rebar splicing processes.

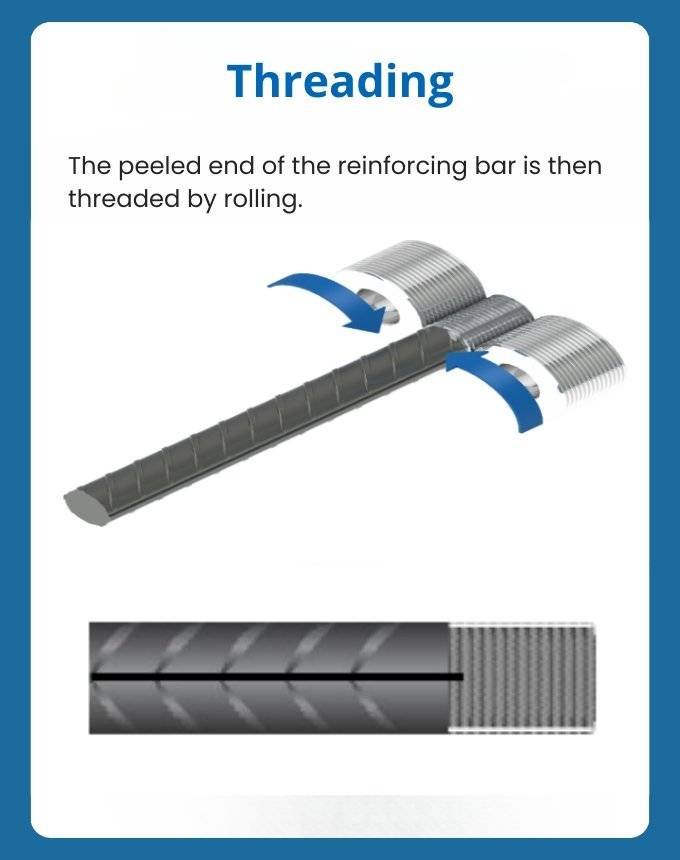

Rebar Roll Parallel Thread

Rebar roll parallel threading is a process where threads are formed on the end of rebars through a rolling operation. This method ensures precise thread dimensions and consistent quality, facilitating easier installation of couplers for reinforced concrete structures. It enhances construction efficiency by allowing quick and reliable rebar connections, crucial for maintaining structural integrity and durability.

Rebar Cold Forging Machine

A rebar cold forging machine is used to create cold-forged couplers, which are essential components in reinforced concrete structures. This machine shapes metal without heating it, ensuring the couplers maintain their strength and durability while providing a secure connection between rebars. It’s a crucial tool in modern construction, offering efficiency and reliability in rebar splicing processes.

VIEW MORE 〉

Rebar Roll Parallel Thread

Rebar roll parallel threading is a process where threads are formed on the end of rebars through a rolling operation. This method ensures precise thread dimensions and consistent quality, facilitating easier installation of couplers for reinforced concrete structures. It enhances construction efficiency by allowing quick and reliable rebar connections, crucial for maintaining structural integrity and durability.

BAR-END PREPARATION

Cold Couplers

1. Forging

The reinforcing bar is enlarged by cold forging process, thus increasing its diameter.

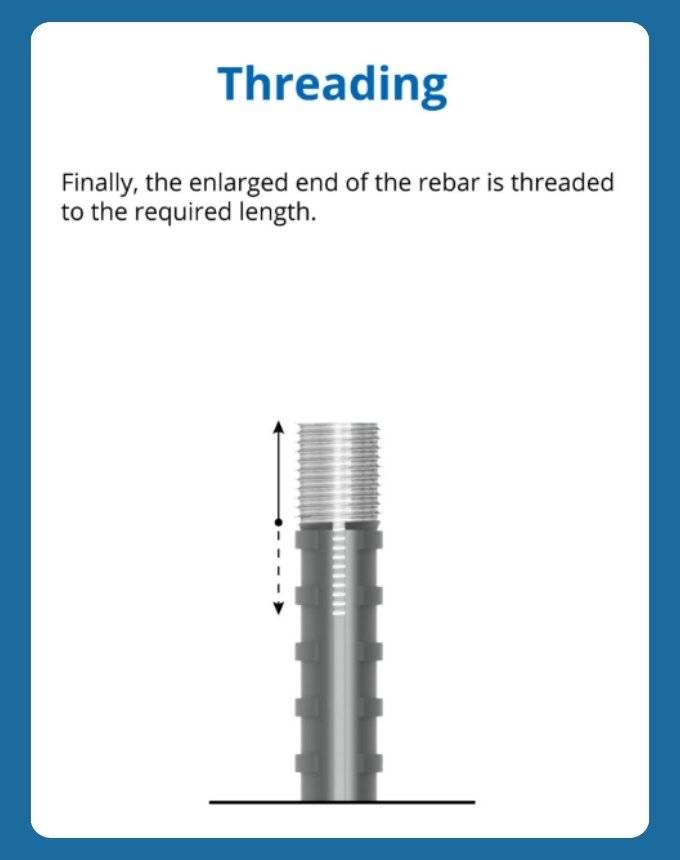

2. Threading

Standard ISO metric threads are then cut on to the enlarged end.

3. Mechanical Splicing

Finally splice the rebar by threaded Couplerhub cold forged coupler.

Parallel Threaded Couplers

1. Peeling

The ribbing at the end of the rebar is peeled.

2. Threading

The peeled end of the rebar is rolled thread as per stand ISO metric.

3. Mechanical Splicing

Coupler can be used to connect the two rebars.

Dıscover Portfolio

Our Latest Projects

Completed Projects

| The Matrix (Nirwan construction) | World business Center |

|

|

Ongoing projects

| SKIT Collage | JVJ Builder |

|

|

| City Home (Century 21One) | AekumHub (Sun & Moon) |

|

|

| Impriya Place (Panchwati Shrikripa) | |

|

Upcoming Projects

Completed Projects

| The Matrix (Nirwan construction) |

|

| World business Center |

|

Ongoing Projects

| SKIT Collage |

|

| JVJ Builder |

|

| City Home (Century 21One) |

|

| AekumHub (Sun & Moon) |

|

| Impriya Place (Panchwati Shrikripa) |

|

Upcoming Projects

Upcoming